In my last post, I excitedly mentioned participating in a Secret Santa craft gift exchange with people who played my favorite game,

Glitch. Sadly, not too long after I posted, Glitch announced that they would shut down as of December 9, 2012. In some ways, I suppose the Mayans were correct, and only off a few weeks - the most beautiful online world I have ever had the privilege to participate in ended. Once I found out the game was over, I threw myself into a number of Glitch-related crafts. For my roommate, whom I met in game, I took a teddy bear I bought on sale at a T.J. Maxx, and I turned him into an emo bear:

|

| The original teddy bear |

|

| Ripping his embroidered eyes out |

|

| An eye half pulled out |

|

| An eye-less teddy bear |

|

| New, more Glitch-like eyes added |

|

| The completed emo bear with the "falling off" tummy patch, striped paw pads, and add on lips and moon. |

|

| As you can see, the lips can be snapped on or left off... |

|

| ... and the moon is held on with elastic |

|

| A close up of the face with... |

|

| ... and without the lips |

|

| The completed bear in all his glory! |

|

The original emo bear I was attempting to replicate.

|

While I feel like my emo bear is a close approximation, it just wasn't enough to show my appreciation for such a wonderful game. I ran a Secret Santa with a group of my friends, and I began thinking that I might use my newly-found skills in stained glass to create something awesome.

I started with the word Glitch in their font and shape:

|

| I just used print screen from their home page |

I then began creating a pattern based on it:

|

| I used Glass Eye to create this. |

I chose the pinkish/red based on what I thought my recipient would like. I went to

Anything in Stained Glass, and started digging through all of their pinks, trying to find the right shade. Sadly, it appears that pink is a more rare color because gold is used in the coloring. After digging out the closest shade I could get, I took my prize home and began work:

|

| I cut out all the pieces. |

|

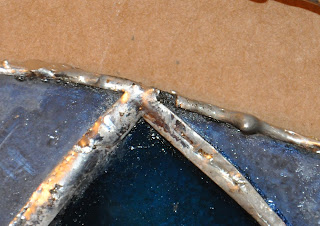

| I foiled and soldered the piece. |

|

| I framed it and added hooks to the sides for a chain. |

|

| And here is a picture of it in the light. |

This time, I only had one issue - I broke the c while soldering. It was an easy replacement, and this piece went much smoother than the last. I sent the piece off to my recipient, and I've been told she absolutely loves it.

At my roommate's, husband's and online friends' encouragement, I decided to speak to Tiny Speck regarding making more stained glass pieces for sale, especially

cubimals. They responded:

"There are a couple of things we need you to do:

1) Don't use the Glitch trademarks (logo/name) in any of the work you sell. The stained glass "Glitch" looks amazing but it's going to have to stay in your personal collection.

2) When selling things, don't say anything that might lead someone to believe that we created or endorsed your work.

Thanks for checking with us!"

They seem to have missed that I gave this piece away already; however, it's my understanding that it's ok because I did not make it for profit. Sadly, this means I cannot make and sell any more of the glitch piece above. However, I have already designed and made three cubimal stained glass items I will show off in another post. (Please note that Tiny Spec/Glitch have not created nor endorsed these items!!)